Showing all 11 results

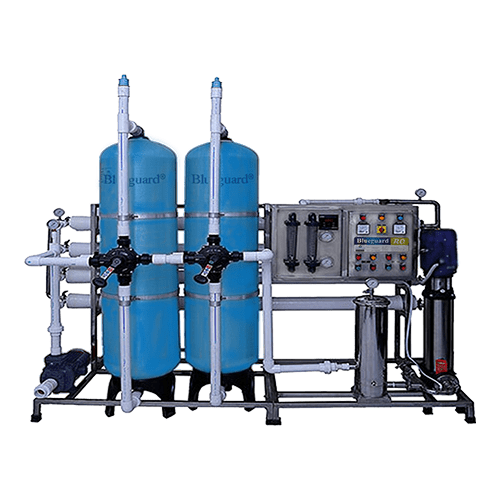

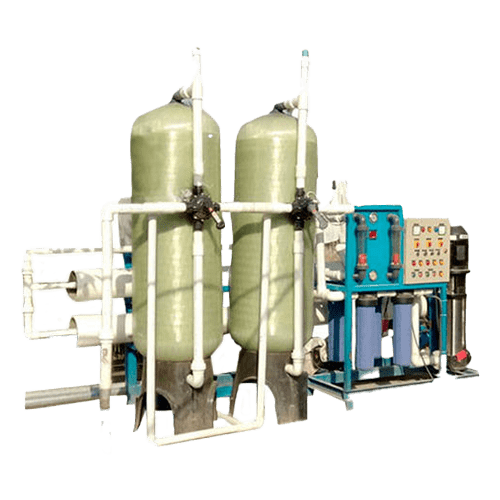

RO Plant In Tuticorin

A reverse osmosis plant is a manufacturing facility that performs reverse osmosis. By forcing water through a membrane, reverse osmosis purifies or desalinates contaminated water. As a result of reverse osmosis, salty briny waste is produced that can be used for desalination,wastewater treatment in Tuticorin, and contaminant concentration.

Freshwater production has been a persistent issue throughout human history. Several factors have hindered the distribution of clean water in many regions, including location, contaminants, temperature, salinity, and dissolved solids. Due to reverse osmosis, this problem has been solved efficiently. The purpose of this article is to give an overview of reverse osmosis technology and its applications to those without a clear understanding of reverse osmosis water.

Through reverse osmosis, dissolved ions are removed from water using advanced filtration technology. Water is drawn to saltier water by osmosis. In this process, dissolved ions are removed from the water. To overcome this elemental force, pumps and semi-permeable membranes are used, which force water treatment in Tuticorin through the membrane and filter out dissolved salt.

RO plant in Tuticorin (REVERSE OSMOSIS): How does it work?

The reverse osmosis process removes unwanted pollutants such as bacteria, viruses, and other microorganisms from water by forcing them through a semipermeable membrane. Ultra-pure water is produced by separating pollutants from water and flushing them out throughout the process.

High-pressure pumps elevate the pressure on the concentrated side of the reverse osmosis system and push the water through membranes. Depending on the number of contaminants present in the feed water, it is a highly effective water treatment in Tuticorin process.

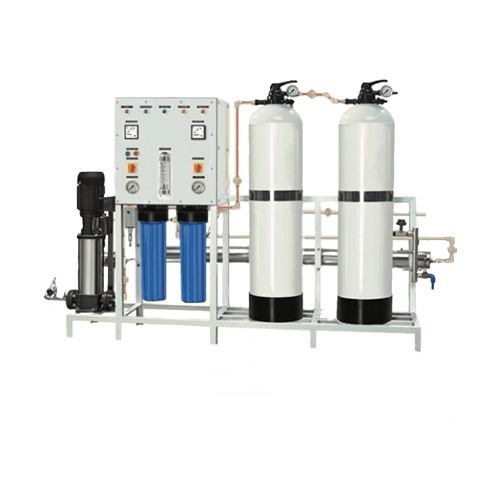

Permeate or product water is purified water that has been removed from its dissolved solids. Reject water is the concentrated stream of contaminants left behind in the brine.

As the feed water passes through the reverse osmosis system, the membrane is responsible for removing all unwanted salts and minerals.

Top-brand membranes (Dupont Filmtec, Hydranautics) can eliminate up to 99% of dissolved solids from water. For water conservation, the rejected stream can be recycled through reverse osmosis.

RO plant in Tuticorin It wouldn’t be so big if it just needed a pump, would it?

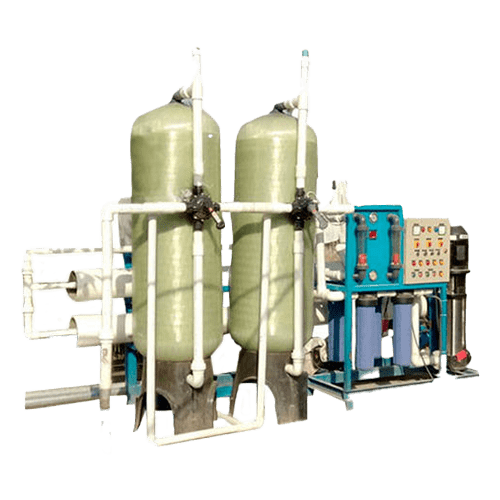

Here is the complete reverse osmosis process, including the pre-and post-treatments needed for highly contaminated water: System for pre-chlorination dosing If the feed water contains traces of heavy metals or is contaminated, it is highly recommended to dose some chlorine. This will convert the dissolved heavy metals to physical form, so the media filter can remove most of them. Tanks for storing raw water most reverse osmosis systems start with a large tank that stores the contaminated water, although some RO plant in Tuticorin systems can draw water directly from a well or pipe.

The initial pressure for the Treatment System is provided by a commercial or industrial pump. A booster pump may be necessary later down the line if the motor does not provide enough water pressure to get through pretreatment and RO plant in Tuticorin membranes.

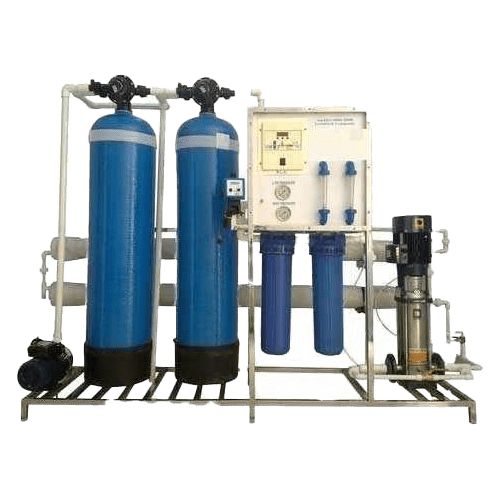

RO plant in Tuticorin Filter with activated carbon

To reduce organic matter, an unpleasant taste, odor, and chlorine in water, carbon filters are a suitable solution. Water softener with automatic regeneration

In small RO plant in Tuticorin systems, we usually recommend water softeners instead of chemical dosing to remove calcium and magnesium ions from the water. The antiscalant chemical dosing system

For larger RO plant In Tuticorin systems, we use antiscalant dosing systems to dose our PA0100 antiscalant RO chemical, which prevents membrane fouling. Visit our CDS-Series chemical dosing pumps for more information. The reverse osmosis system or reverse osmosis system is finally up and running. It is typically just before this step that a booster pump will be required. From a steady intake, the reverse osmosis system can produce up to one million gallons of product water a day.

Tanks for storing product water. Reverse osmosis permeate is usually stored in a large tank. If it didn’t, the system would need to be the system would have to be running to access fresh water if it didn’t, the system pumps water directly into a well, or aqua systems are sometimes used for recharging wells or aquifers instead of being used in typical industries or applications.

Post-Chlorination Dosing system is highly recommended to dose some chlorine into the permeate water if it will be stored for more than one day. Pump for repressurizing the product water repressurizes the permeate water until it reaches the point of use based on the overall travel distance and required head, this is selected.d. TIn order to prevent contamination of the permeate water, this pump must be made from stainless steel.

UV Sterilizer for Product Water As a final disinfection device, the UV sterilizer is placed after the storage tank. Moses is a disinfectant, we usually use post chlorinationultraviolet sterilization.

What Is the need for prevention in RO plant in Tuticorin?

In reverse osmosis systems, the feed water must be preconditioned to prevent fouling and premature failure of the membranes. RO plant in Tuticorin membranes operates similarly to cross-flow filters. They are made of a porous material that allows water to pass through but rejects up to 99% of dissolved solids. in reverse osmosis reject water, or brine reverse osmosis reject water, or brine stream, contains the dissolved salts, which dissolved and suspended solids in the feed water tend to accumulate along the membrane surface as the RO plant in Tuticorin system operates.

The accumulation of these solids eventually restricts the passage through the membrane, resulting in the loss of throughput. (The throughput capacity of this membrane’s throughput capacity is commonly referred to as its flux rate, and is measured in gallons per square foot of membrane surface area per day.

It has been shown that the foulants in failed membrane modules are caused by mineral scales, such as calcium carbonate; colloidal materials, such as clays and silicas; dead and living microorganisms; carbon particles; and chemicals attached by oxidizing agents, such as chlorine, ozone, or permanganate.